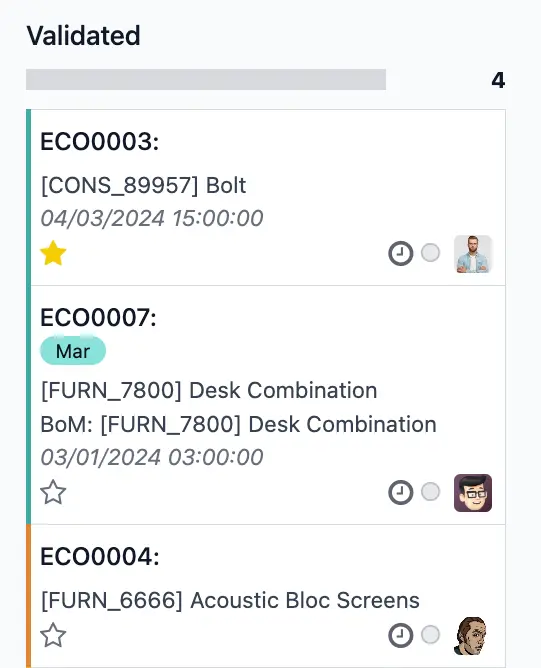

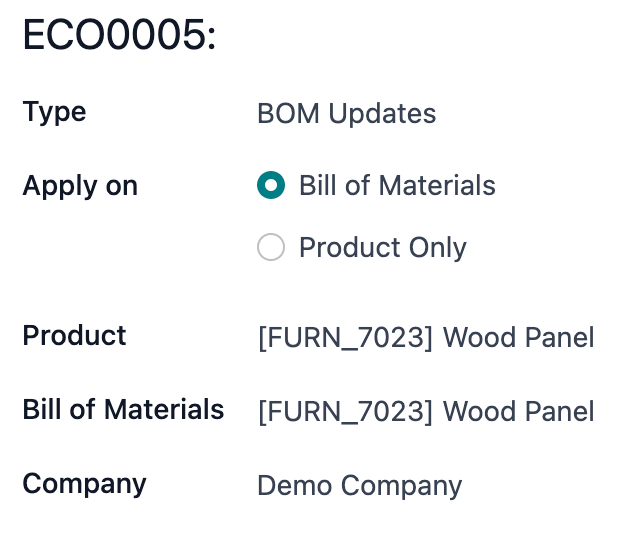

Manage your

Product Life Cycle

Unexpected events can always happen in the production process, you may have relatively low orders in certain seasons, and during a period of growth, the volume of orders may rise, you might get a lot more orders, requiring you to change your production plans.

Product Life cycle (PLM) app in Odoo,

helps engineers in modifying or refining production plans, materials, or components within the BOM. It ensures that these modifications or changes are carried out systematically and can be verified.

Manage your

Product Life Cycle

Product Life cycle (PLM) app in Odoo,

helps engineers in modifying or refining production plans, materials, or components within the BOM. It ensures that these modifications or changes are carried out systematically and can be verified.

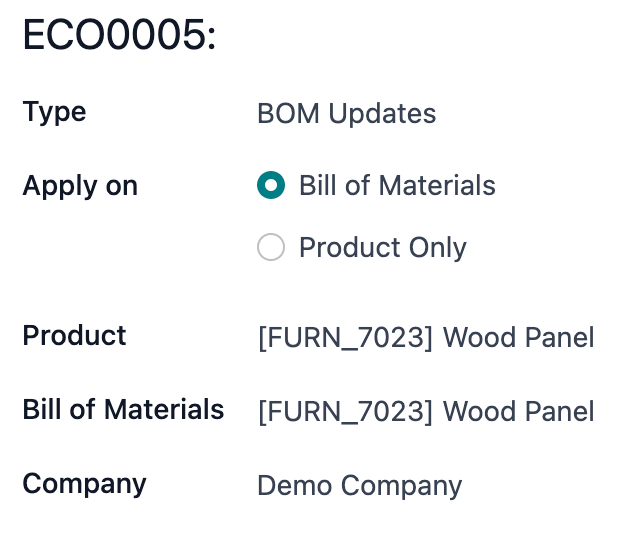

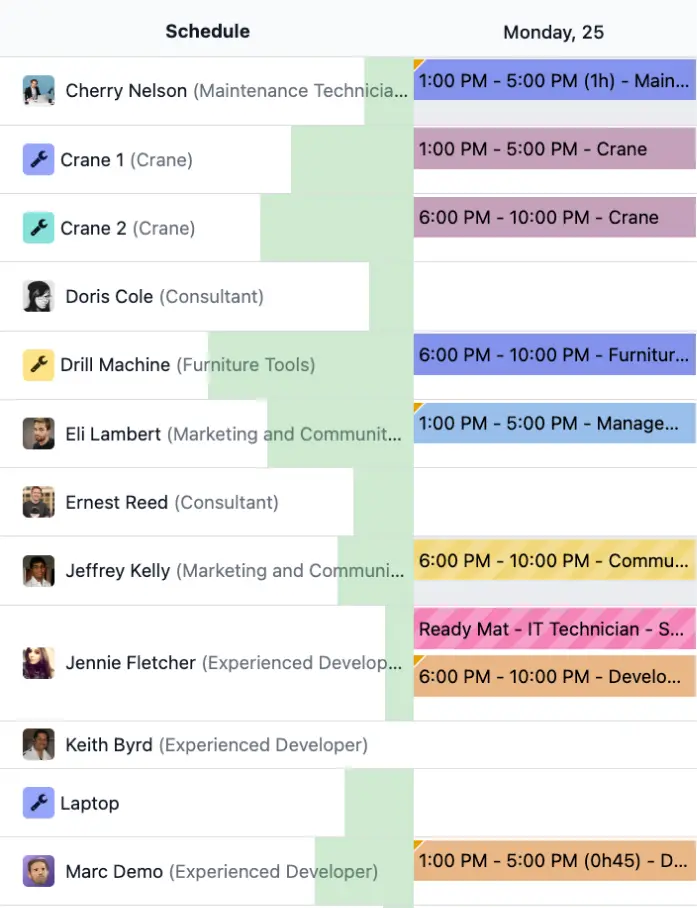

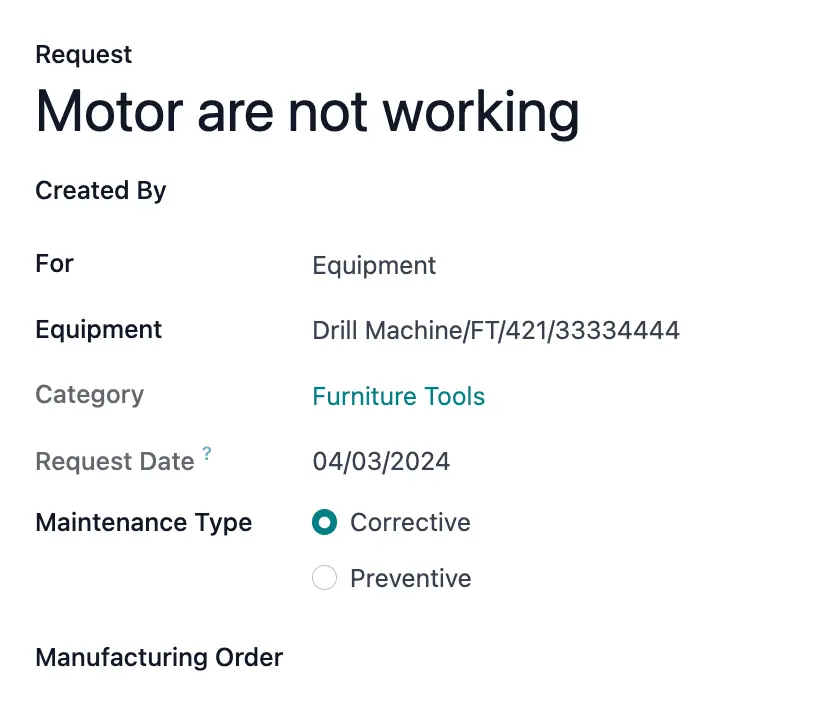

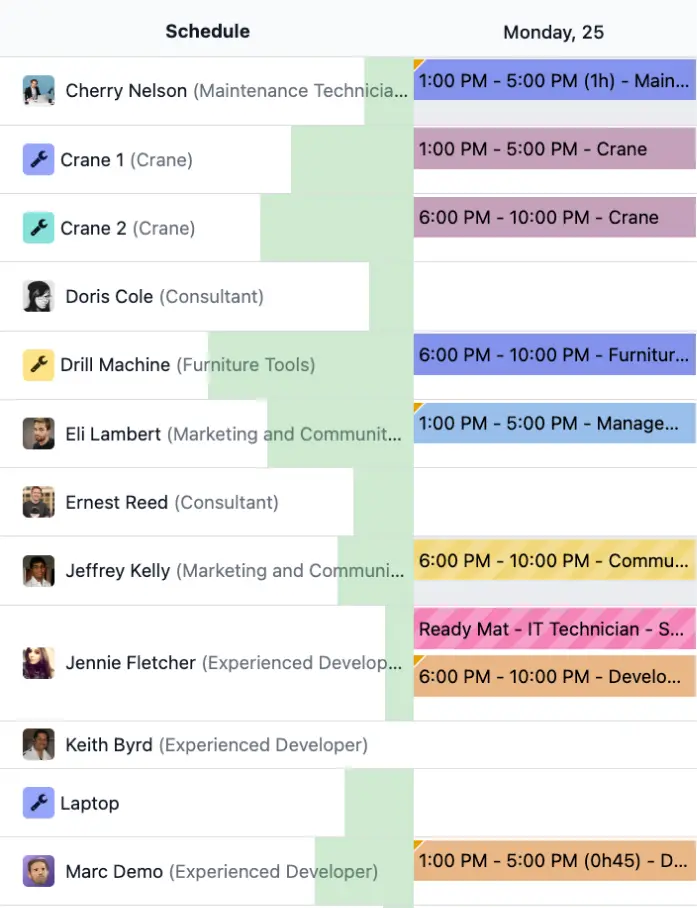

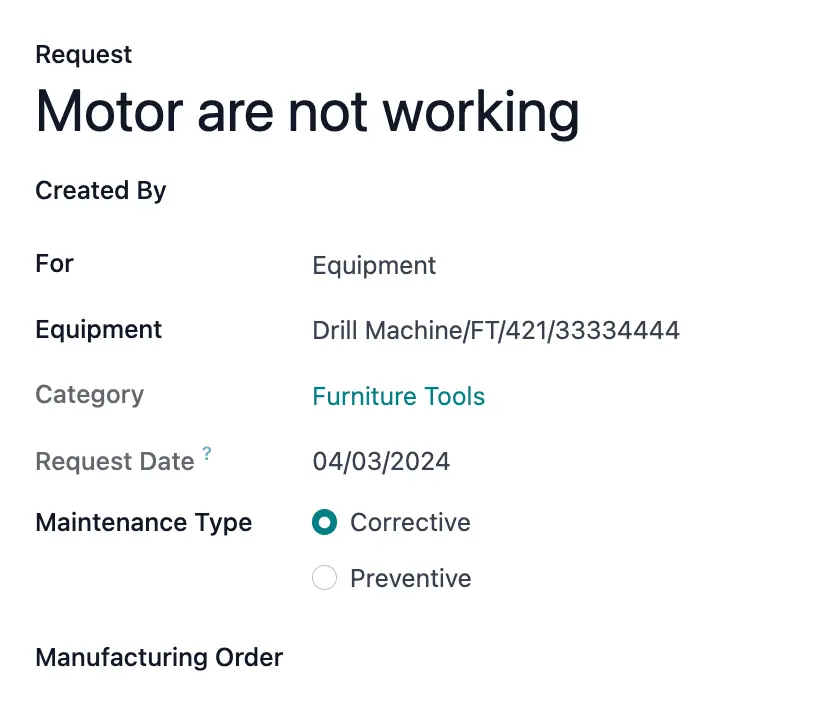

Aligning

Machinery Workload & Shift Workers

Within the factory, it's not just products and raw materials that you have to manage. You also have machinery and shift workers, which require planning to align the workload and production with your product sales volume.

Odoo provides functions that allow you to set up Time Efficiency, Capacity, OEE Target, or even setup the cleaning time during production. You can utilize worksheet, manage work center, and use the planning features in Odoo. This ensures that your factory operates efficiently and maximizes productivity.

Planning your shifts and schedules in Odoo enables you to optimize your workforce management, ensuring that you have the right number of skilled staff members available at the right time to.

Aligning

Machinery Workload & Shift Workers

Within the factory, it's not just products and raw materials that you have to manage. You also have machinery and shift workers, which require planning to align the workload and production with your product sales volume.

Odoo provides functions that allow you to set up Time Efficiency, Capacity, OEE Target, or even setup the cleaning time during production. You can utilize worksheet, manage work center, and use the planning features in Odoo. This ensures that your factory operates efficiently and maximizes productivity.

Planning your shifts and schedules in Odoo enables you to optimize your workforce management, ensuring that you have the right number of skilled staff members available at the right time to.

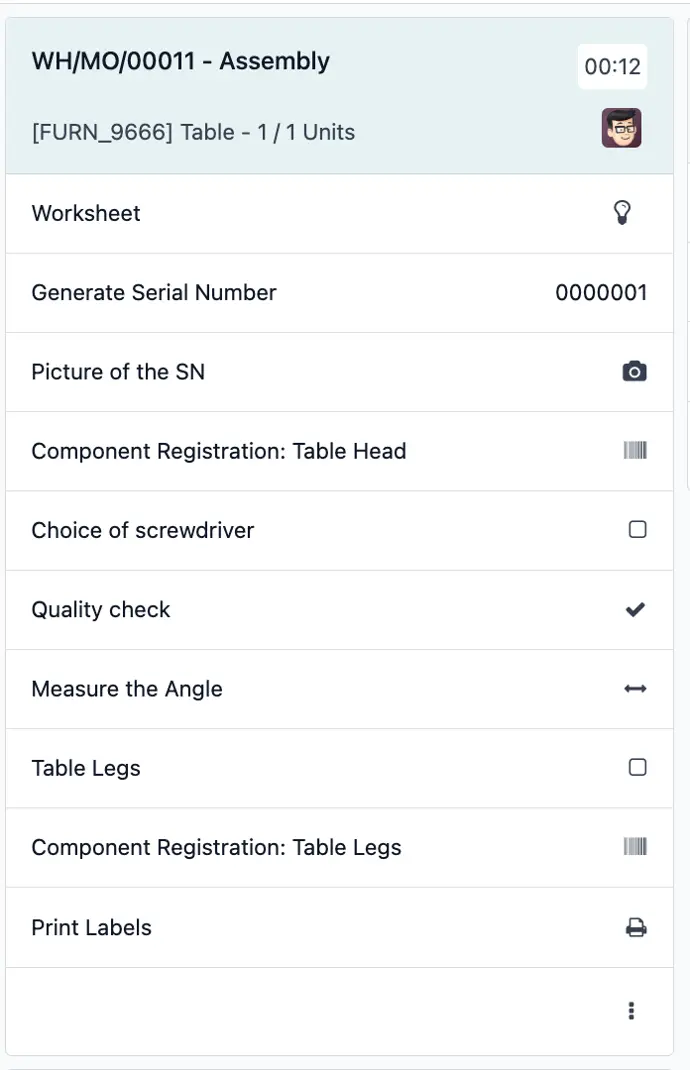

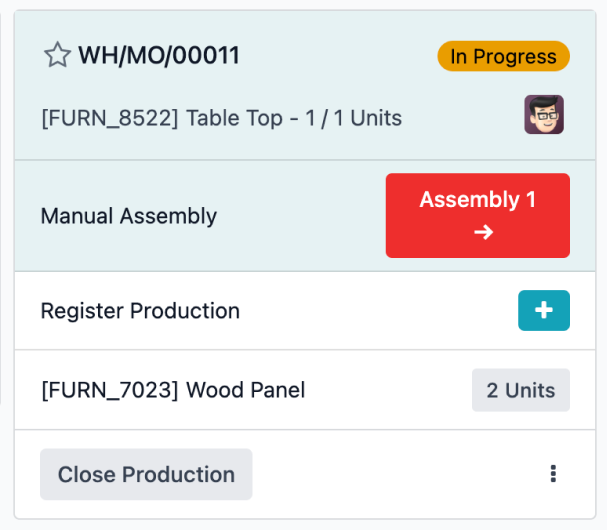

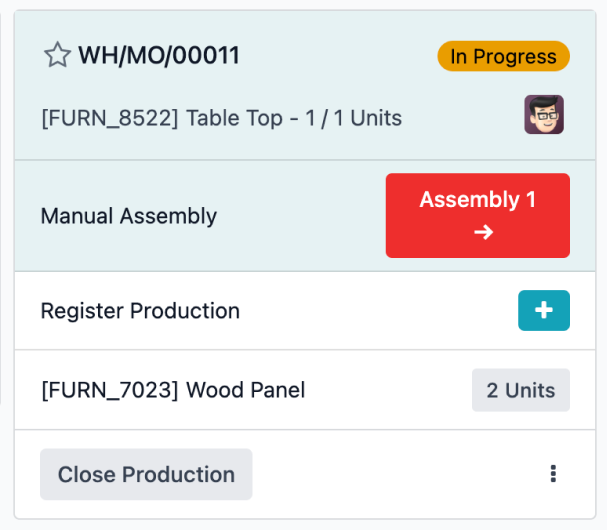

Record the operation in

Manufacturing on a tablet.

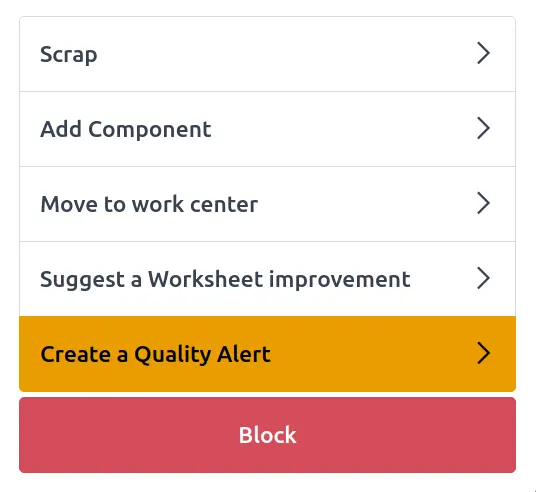

In addition to production planning, the manufacturing processes, which will be carried out by workers on the production line, need to be recorded by the production line supervisors. Odoo provides this capability within the 'Shop floor' module.

Simply use a single tablet to inspect and record the processes, This includes reporting issues and recording temporary production stoppages for any reason. And it can coordinate with the QC department, which will use the QC app to inspect the product quality after production or assembly.

Record the operation in

Manufacturing on a tablet.

In addition to production planning, the manufacturing processes, which will be carried out by workers on the production line, need to be recorded by the production line supervisors. Odoo provides this capability within the 'Shop floor' module.

Simply use a single tablet to inspect and record the processes, This includes reporting issues and recording temporary production stoppages for any reason. And it can coordinate with the QC department, which will use the QC app to inspect the product quality after production or assembly.

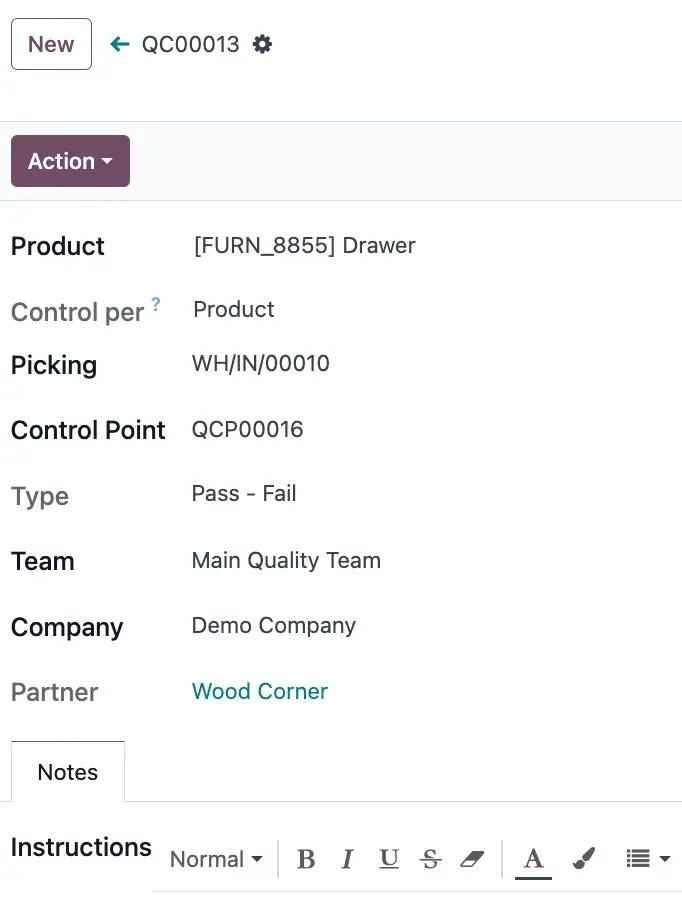

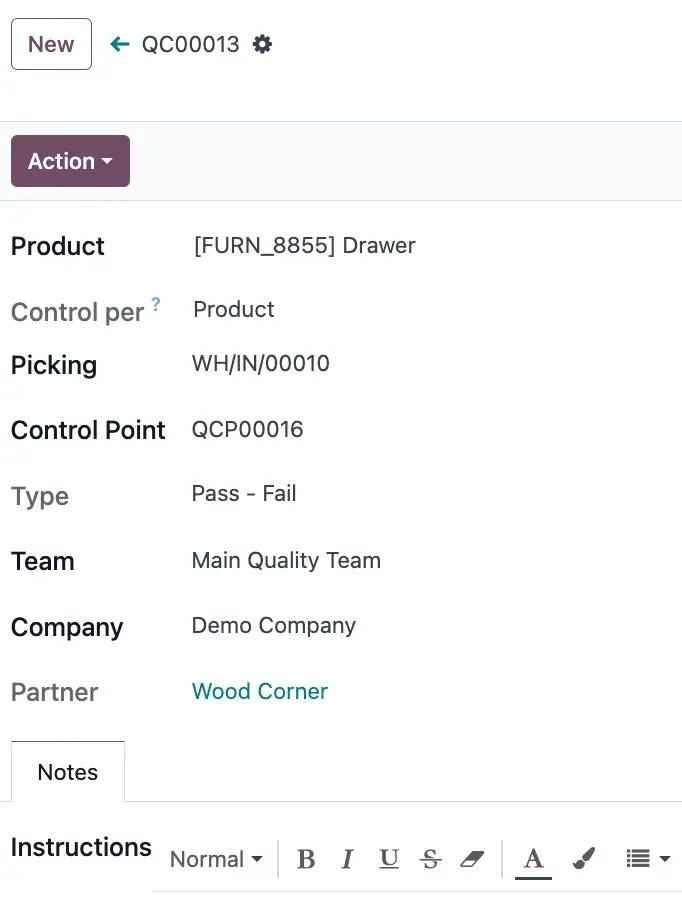

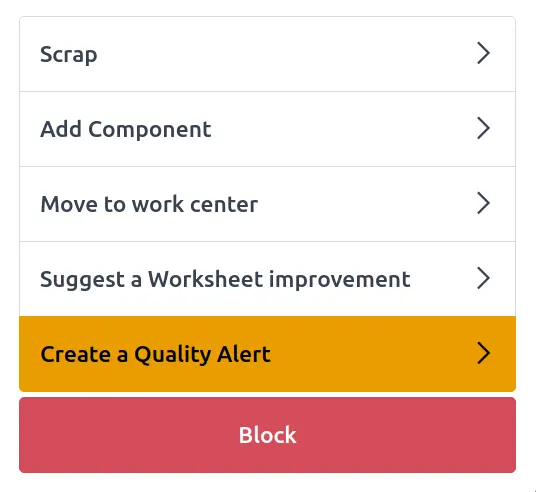

Facilitate any condition for

Quality Check

Odoo can help you with inspection starting from items receipt from suppliers, raw material inspection before production, and of course! after completed production.

You can set conditions based on random quantity, inspect all items, inspect only certain products, measure dimensions, or even create custom inspection as needed, Also define post-inspection steps for products found to be of insufficient quality.

Customize your conditions for

Quality Check

Odoo can help you with inspection starting from items receipt from suppliers, raw material inspection before production, and of course! after completed production.

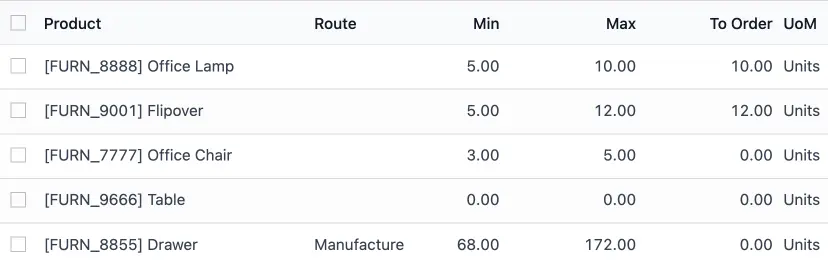

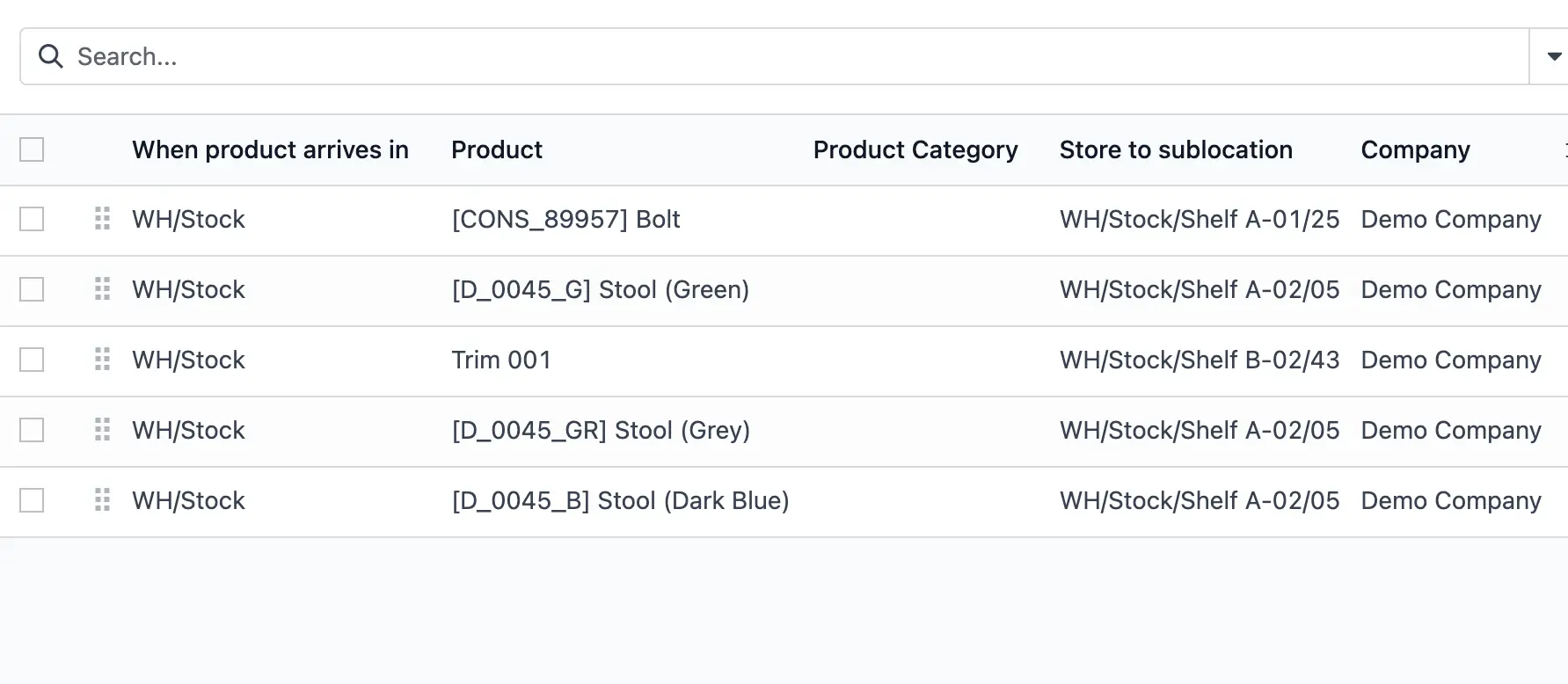

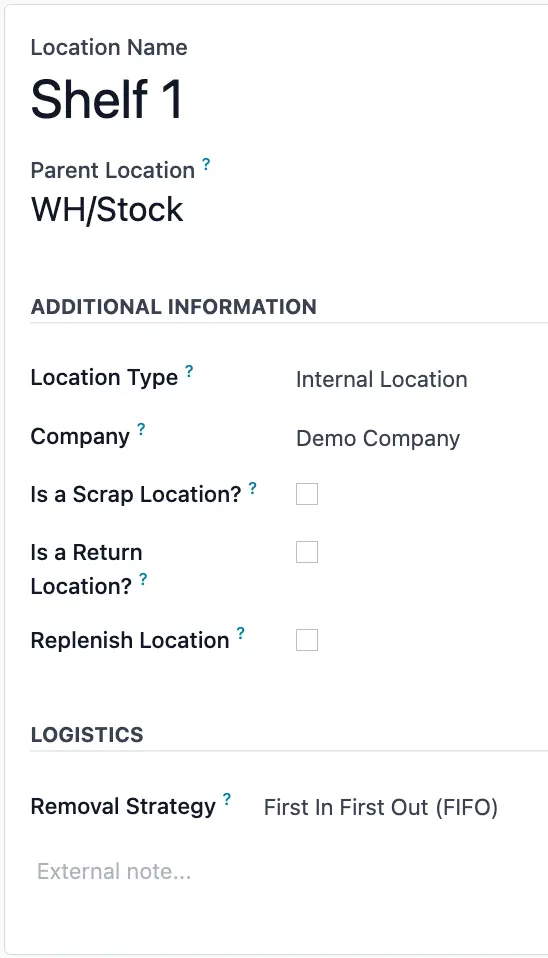

Automated transactions for

Inventory management.

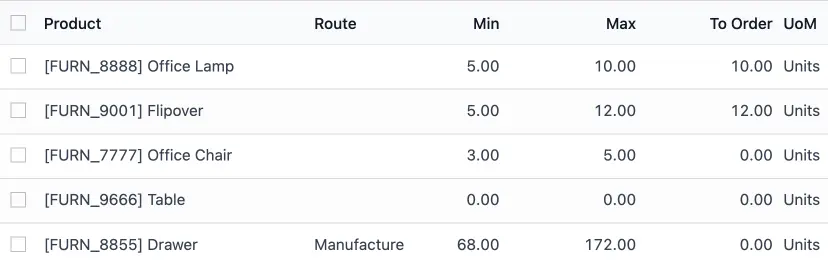

Managing production becomes easier with Odoo's reordering rule function, which helps automate the creation of purchase orders or manufacturing orders when product quantities reach a specified minimum level.

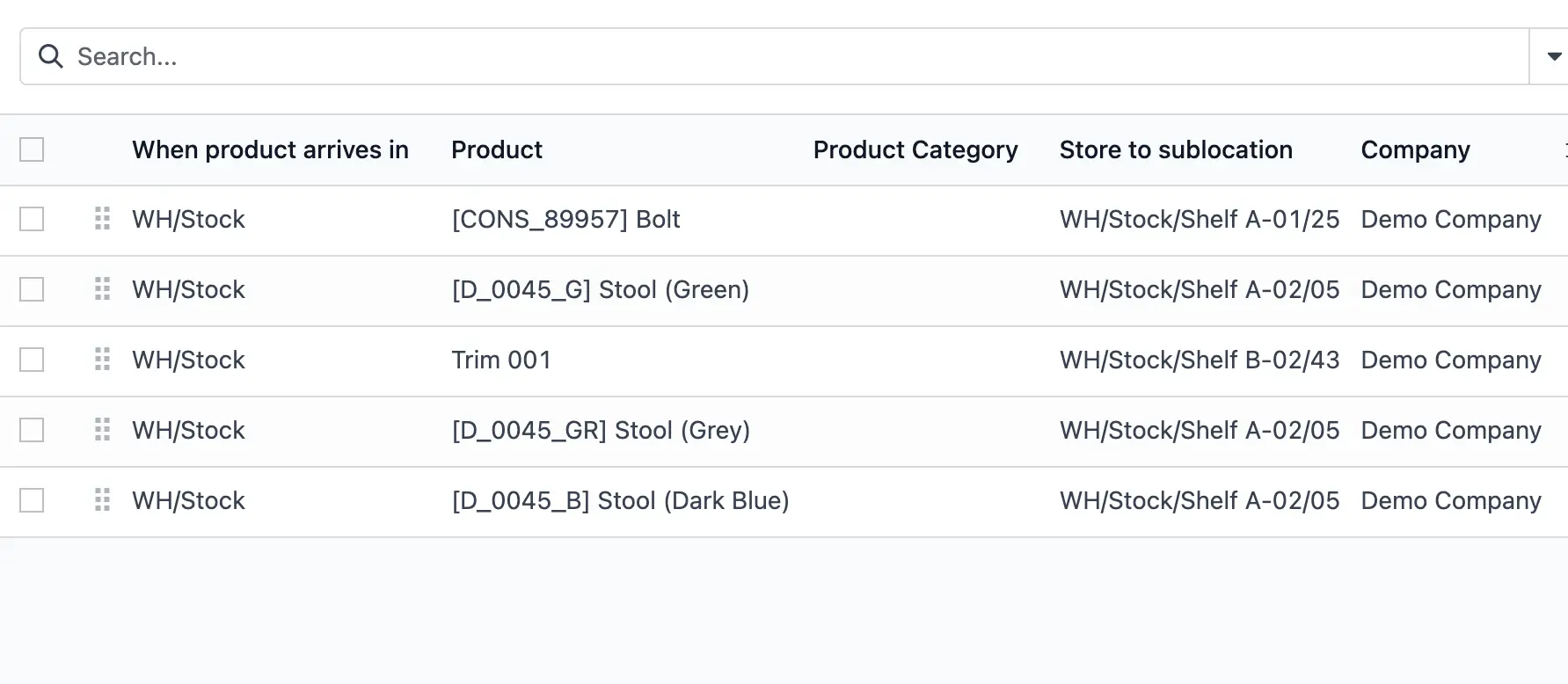

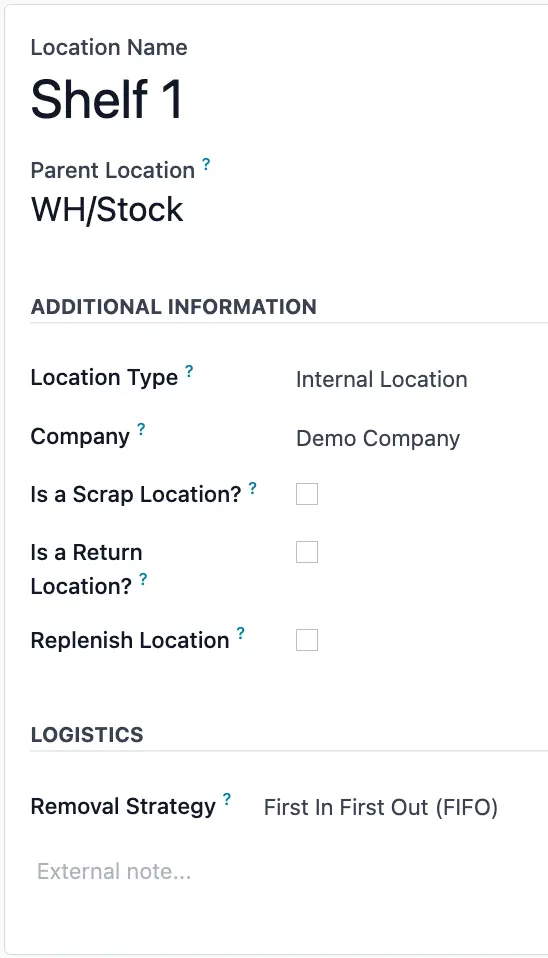

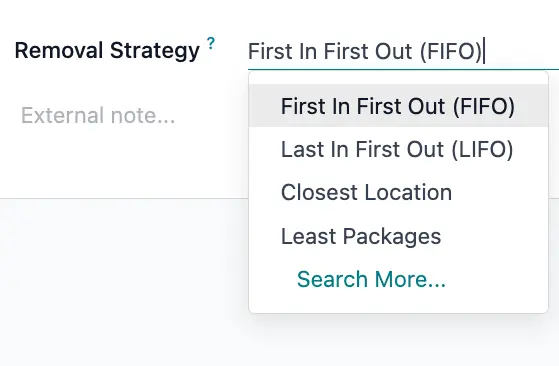

And you can create rules for material picking before production or for selecting storage locations after production to ensure quality storage.

Automated transactions for

Inventory management.

Managing production becomes easier with Odoo's reordering rule function, which helps automate the creation of purchase orders or manufacturing orders when product quantities reach a specified minimum level.

And you can create rules for material picking before production or for selecting storage locations after production to

ensure quality storage.

Back Office &

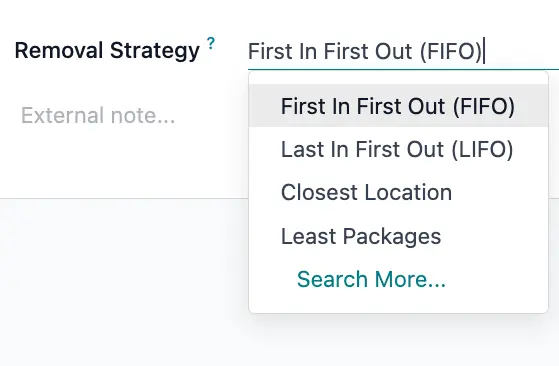

Accounting Management

Odoo's accommodates various costing including standard costing, average costing, FIFO, and others.

And allows for different costing methods for individual product categories, enhancing flexibility in cost analysis and management by manufacturing and inventory operations, cost analyses are generated based on configured settings,Including support for Thai localized accounting.

Back Office &

Accounting Management

Odoo's accommodates various costing including standard costing, average costing, FIFO, and others.

And allows for different costing methods for individual product categories, enhancing flexibility in cost analysis and management by manufacturing and inventory operations, cost analyses are generated based on

configured settings, Including support for

Thai localized accounting.

Schedule Demo Session Free!

Our expert team is ready to guide you through the features,

benefits, and insights tailored to your business need.

Experience your demo here.